Understanding Aluminium Extrusion Better.

Aluminum is a silver-white metal that is found abundantly in the earth’s crust. The reasons for this metal’s high demand in the industrial world are its physical features – high strength, lightweight, and resistance to corrosion.

What is Extrusion of Aluminum?

In its extrusion format, aluminum is widely used.

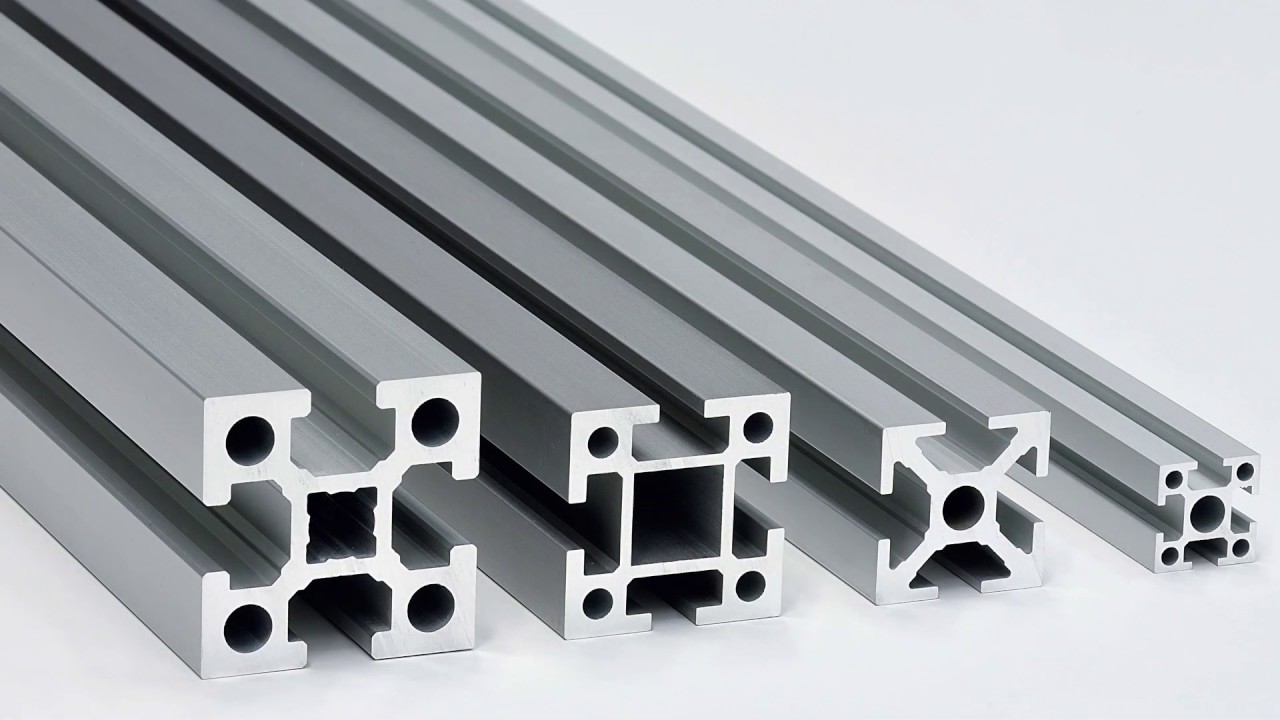

A process used to create fixed cross-sectional aluminium profile objects. The two main benefits of other methods are creating complex cross-sections and working with fragile materials, as they are only subjected to compression and shear stress. It also forms finished pieces with an excellent finish on the surface. Aluminum is one-third of the density and rigidity of steel that allows it to be bent into different forms and castings without affecting strength and stability.

Aluminum extrusion process

For the production of aluminum extrusions, the design is first developed to make the die-cast. A well-designed die cast has several advantages, including high-quality extrusion output, maximum extrusion use, and minimum use of alloy material. The company’s designers should ideally work together with die-cast and engineers to create the design that everything offers.

The next step is extrusion, which is done using either the hot or cold chamber processes.

Pre-heated material is loaded in the chamber in hot chamber extrusion in which the cast is already placed. Pressure is used for the removal of the alloy material from the die. Liquid nitrogen is sometimes added to prevent oxides in the extrusion.

At room temperature, the cold extrusion is done. Excess pressure is used to remove the material from the diet. This process gives the surface finish faster, stronger, and better compared with the hot process.

After extrusion is performed and material is refreshed (when heat chamber is processed), it is cut into desired lengths.

Finally, aluminum is hardened and aged by heating it in aging stoves.

Aluminum Extrusion Benefits

The extrusions are more substantial and thus easier to move around because there are no sold joints. This also makes it straightforward to assemble extrusions. In addition, the surface finish is smooth, and the design looks attractive. The extrusions are used in various sectors, including automotive, retail, buildings, displays, stage setting, brand names, and many more.